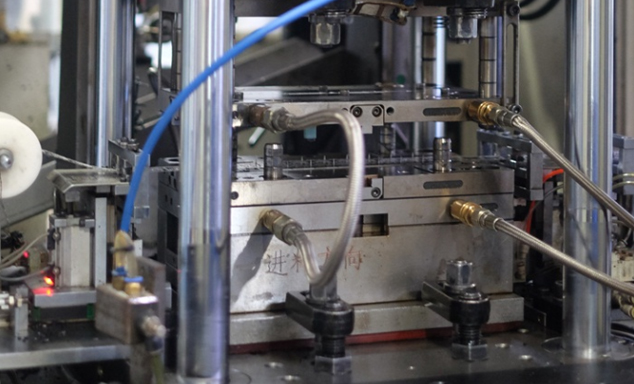

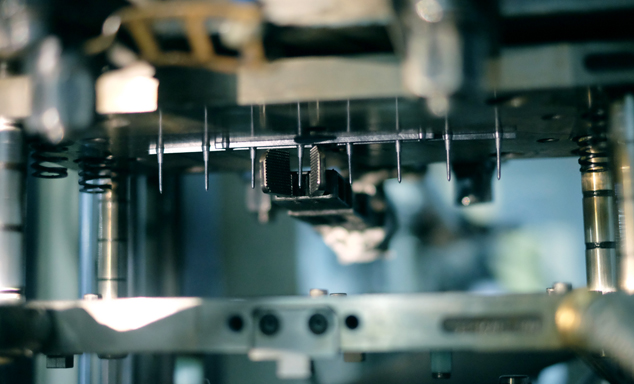

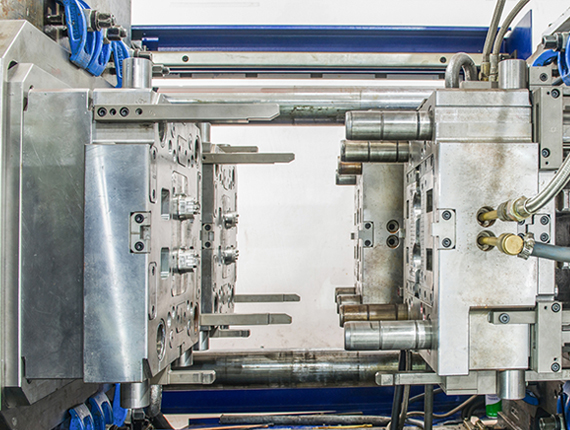

To meet customer demand from different industry, ISEN introduced over 60 sets of DEMAG, NISSEI, Haitian fully automatic injection machines ranging from 25 ton to 530 ton from Germany, Japan, etc. All the machines are all well equipped with Robots advanced from Japan, which can precisely control the injection pressure, speed and ejection location, and make sure the quality to be steadier. Our company can produce high precision injection parts---CD-Rom lens stents with 0.01g minimal weight, 0.20mm minimal wall depth.

Injection workshops can be divided into common and non-dust portion (mainly produce the mirror surface parts), arranging production per parts different requirement. Equipping with high-power (100KW) Central Cooling System, the super cooling effect greatly improve our production efficiency; Over 30 sets of constant equipments can separately adjust the temperature for each injection mold, which make sure the parts quality can reach a steady status; Especially the Economic Vacuum Drying Machines guarantee the precision molding parts with high precision, high intension and perfect cosmetic appearance.

ISEN owns more than 10 professional plastic molding engineers, molding technicians who have skillful working experience on precision injection molding and cosmetic parts.

ISEN regard Human-Basing as our core conception, providing the chance of communicating technique with outside, arranging training, studying regularly for our current technical works.