- 最新文章

-

Connector to precision plastic mold manufacturing manufacturers high requirements

Connector to precision plastic mold manufacturing manufacturers high requirements -

Automotive stamping die manufacturing requirements for machine tools and tools

Automotive stamping die manufacturing requirements for machine tools and tools -

Shenzhen mold parts industry technology in the market impact of the new breakthrough

Shenzhen mold parts industry technology in the market impact of the new breakthrough -

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world -

Precision plastic mold processing process

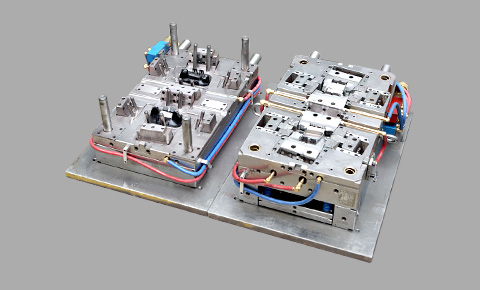

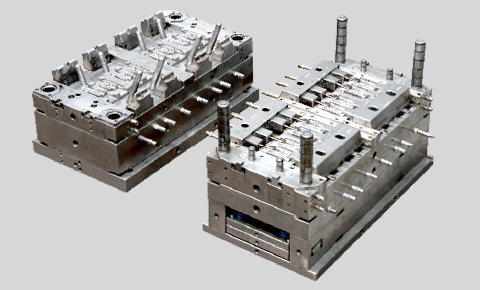

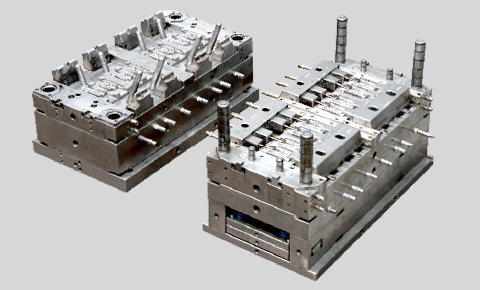

Precision plastic mold processing process

Precision plastic mold processing process

In our mold factory, mold processing is a very important production and processing process. Die processing refers to the molding and billet tool processing, in addition to shear die and die - cutting die. Then precision plastic mold processing process is what kind of? Usually, the mold has two parts: upper die and lower die. The steel plate is placed between the upper and lower molds, and the material is formed under the action of the press. When the press is opened, the workpiece determined by the mold shape will be obtained or the corresponding waste will be removed. Specific precision plastic mold processing process:

1, the processing of the bottom, processing quantity guarantee;

2. Check casting blank datum alignment, 2D and 3D mold surface allowance;

3. Rough machining of 2D and 3D surface, non-installation and non-working surface machining (including safety platform surface, buffer mounting surface, pressure plate surface and side datum surface);

4. Before semi-finishing, alignment of the side datum level ensures the accuracy;

5, semi-finishing type, 2 d and 3 d surface, finish all kinds of installation face (including installed limit block surface and contact surface, panel board surface and on the back, the punch surface, waste cutter installation surface and on the back, spring mounting surface and contact surface, all kinds of travel restrictions on working face, inclined wedge installation surface and on the back), semi-finishing guide, guide hole, leave allowance for finish machining process benchmark hole and height datum, and record data.

6. Inspect and review the machining accuracy;

7. Setting and working procedure of locksmith;

8, before finishing, process datum hole datum level alignment, insert allowance check;

9, fine processing surface 2D, 3D, side punching surface and hole position, finishing process datum hole and height datum, finishing guide surface and hole;

10. Check and review the machining accuracy.