News

- 最新文章

-

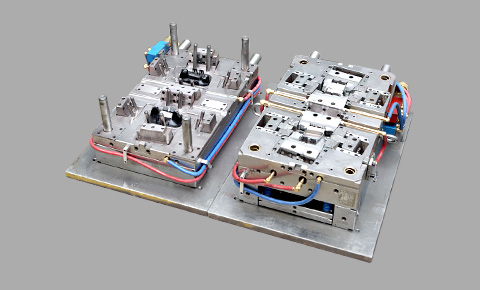

Connector to precision plastic mold manufacturing manufacturers high requirements

Connector to precision plastic mold manufacturing manufacturers high requirements -

Automotive stamping die manufacturing requirements for machine tools and tools

Automotive stamping die manufacturing requirements for machine tools and tools -

Shenzhen mold parts industry technology in the market impact of the new breakthrough

Shenzhen mold parts industry technology in the market impact of the new breakthrough -

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world -

Precision plastic mold processing process

Precision plastic mold processing process

Industry Trends

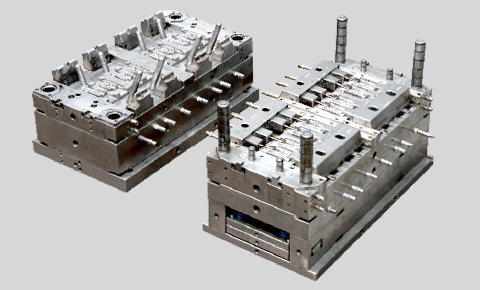

Automotive stamping die manufacturing requirements for machine tools and tools

Automotive stamping die manufacturing requirements for machine tools and tools

2. Requirements for cutting tools

The requirements of the tool, the author has talked about, there are the following points:

1) quality. Quality is the premise, and the quality requirements are endless. The total service life and the grinding life of a blade are measured.

(2) the price. The more competitive the field, the greater the role of price. Cost performance is its measure index.

(3) research and development ability. The ability to launch new products includes at least two aspects: one is the ability to respond to customer needs. Users are afraid of tool suppliers' indifference to their needs. For example, customers strongly recommend products that they do not need at present, while customers are slow to provide solutions for products they need, which is confusing. But now there is a big change, we see some mature targeted solutions; Second, the design and manufacturing capacity of new products, which is a test of the technical manufacturing strength of suppliers.

Of course, not all customer requirements are reasonable or feasible, but suppliers (including ourselves as suppliers of others) do have the obligation to carefully analyze customer needs and provide customers with professional solutions based on the existing technical level. Therefore, whether we can provide professional or targeted technical solutions for customers based on the existing technical level has become a very important and realistic test of suppliers' research and development ability.

(4) delivery time. At present, the reduction of inventory has become all fully competitive industries must face the subject, so the shorter delivery time is particularly important. Close to the customer to establish a reasonable inventory becomes a realistic solution, the closer the faster. Tool suppliers are no exception.

Typical enterprise: dongfeng die punch

Simple die industry is a technology-intensive, capital-intensive, labor-intensive industry, large investment, long payback period, so it is difficult to quickly grow, simple stamping business is relatively easy to grow but lack of core technical support. Dongfeng die stamping technology co., LTD. Through the large stamping business to support the rapid development of die business, mold, stamping interaction, mutual promotion.

Dongfeng die stamping company is established by integrating the tooling and punching welding manufacturing resources of the three original companies under dongfeng. The business scope has been expanded from the past single product to the current integrated products of tooling, stamping and welding, which can provide different products and more extensive services for different users. The total assets of the company exceed 1 billion yuan, with nearly 2,000 employees. In 2008, the sales revenue reached 740 million yuan.

At present, "digital manufacturing" has covered the whole process chain of the company's mold design and manufacturing, and the application of PDM technology has realized the collaborative management of the whole process. In general, dongfeng die stamping has the comprehensive strength of developing, designing and manufacturing 1.5 complete automobile body molds, stamping production and assembly welding every year. It is an important force serving China's automobile industry.

1. Requirements for machine tools and equipment

Automobile stamping die manufacturing equipment requirements, mainly reflected in the stability and reliability.

Mold manufacturing enterprises have great expectations for the equipment they spend a lot of money to buy, which requires all parties to work hard to achieve their predetermined goals and achieve win-win and harmony. If the equipment manufacturers can regularly visit users and door-to-door service, or even some overhaul services and transformation, so much the better.

2. Requirements for cutting tools

The requirements of the tool, the author has talked about, there are the following points:

1) quality. Quality is the premise, and the quality requirements are endless. The total service life and the grinding life of a blade are measured.

(2) the price. The more competitive the field, the greater the role of price. Cost performance is its measure index.

(3) research and development ability. The ability to launch new products includes at least two aspects: one is the ability to respond to customer needs. Users are afraid of tool suppliers' indifference to their needs. For example, customers strongly recommend products that they do not need at present, while customers are slow to provide solutions for products they need, which is confusing. But now there is a big change, we see some mature targeted solutions; Second, the design and manufacturing capacity of new products, which is a test of the technical manufacturing strength of suppliers.

Of course, not all customer requirements are reasonable or feasible, but suppliers (including ourselves as suppliers of others) do have the obligation to carefully analyze customer needs and provide customers with professional solutions based on the existing technical level. Therefore, whether we can provide professional or targeted technical solutions for customers based on the existing technical level has become a very important and realistic test of suppliers' research and development ability.

(4) delivery time. At present, the reduction of inventory has become all fully competitive industries must face the subject, so the shorter delivery time is particularly important. Close to the customer to establish a reasonable inventory becomes a realistic solution, the closer the faster. Tool suppliers are no exception.

Typical enterprise: dongfeng die punch

Simple die industry is a technology-intensive, capital-intensive, labor-intensive industry, large investment, long payback period, so it is difficult to quickly grow, simple stamping business is relatively easy to grow but lack of core technical support. Dongfeng die stamping technology co., LTD. Through the large stamping business to support the rapid development of die business, mold, stamping interaction, mutual promotion.

Dongfeng die stamping company is established by integrating the tooling and punching welding manufacturing resources of the three original companies under dongfeng. The business scope has been expanded from the past single product to the current integrated products of tooling, stamping and welding, which can provide different products and more extensive services for different users. The total assets of the company exceed 1 billion yuan, with nearly 2,000 employees. In 2008, the sales revenue reached 740 million yuan.

At present, "digital manufacturing" has covered the whole process chain of the company's mold design and manufacturing, and the application of PDM technology has realized the collaborative management of the whole process. In general, dongfeng die stamping has the comprehensive strength of developing, designing and manufacturing 1.5 complete automobile body molds, stamping production and assembly welding every year. It is an important force serving China's automobile industry.