- 最新文章

-

Connector to precision plastic mold manufacturing manufacturers high requirements

Connector to precision plastic mold manufacturing manufacturers high requirements -

Automotive stamping die manufacturing requirements for machine tools and tools

Automotive stamping die manufacturing requirements for machine tools and tools -

Shenzhen mold parts industry technology in the market impact of the new breakthrough

Shenzhen mold parts industry technology in the market impact of the new breakthrough -

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world

The demand of automobile mould is huge, and the output value of Chinas mould industry leads the world -

Precision plastic mold processing process

Precision plastic mold processing process

Connector to precision plastic mold manufacturing manufacturers high requirements

Connector, as a port to transmit signals, has been widely used in various industries, such as mobile phones, computers, program-controlled switching, home appliances and other fields. At present, foreign manufacturers occupy the high-end connector market, while domestic manufacturers are still mainly at the low end, which is partly affected by the connector mold industry level.

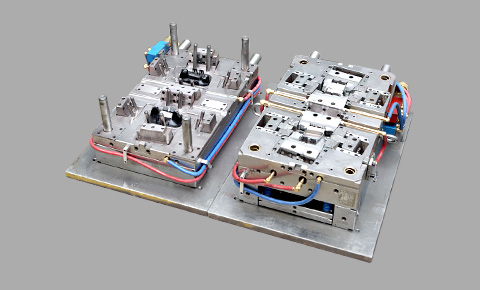

As the connector mold involves injection molding, terminal stamping, electroplating and other aspects, guosheng mainly produces terminal stamping mold, the products include SIM card terminal mold, computer CPU slot STOCK terminal mold, electrical terminal mold and so on.

In the connector terminal mold, domestic manufacturers to low-end, and guosheng mainly for high-end fields. Guosheng international connector manufacturers such as AMP, molex and other well-known manufacturers supporting.

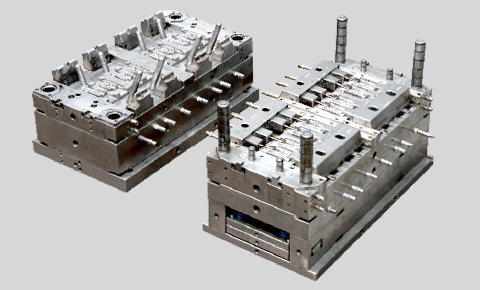

Connector to the mold manufacturing industry requirements are very high: one is the need for a high level of mold design, because different shapes of terminals, connectors have different structures, how to carry out reasonable design is very important, if the structure is not to lead to disqualification of the product. The second is high precision equipment, connector terminals require high precision processing equipment, foreign equipment precision can reach + 0.002mm, and the general country.

The production equipment can only reach 0.01mm. Third, good basic processing technology. A good connector mold needs a perfect combination of design, equipment and process. At the same time, it has higher requirements for equipment matching and higher technical barriers. Guosheng adopts advanced CNC plane grinding, automatic optical curve grinding, slow wire cutting, machining center and other equipment combination for production.

In the future, the requirement of connector terminal mould is higher and higher, which is due to the trend of connector interface miniaturization and high data transmission rate. Therefore, this requires higher requirements for mold equipment, materials, quality, etc., and the stamping speed of the punch used in the mold has reached 500rpm to 3000rpm, which puts forward higher requirements for the mold enterprises.

Guosheng always has advantages in the following aspects: first, it constantly invests in equipment, because only by investing in the most advanced equipment, can it introduce the highest level of technology and technology, and then carry out research and innovation. At present, the wire cutting and 4-axis processing equipment required by connector molds have been manufactured by domestic manufacturers. Although there are still gaps in precision and stability, this is a good start. The second is to carry out talent training, in order to go out, please come in, and constantly improve the technical level of guosheng.

In addition to the connector terminal mold, guosheng household air conditioning radiator mold, motor mold, gun mold, integrated circuit mold in the market is also widely welcomed. Guosheng plans to become one of the top five mold manufacturers in the world within five years. In another 10-15 years, it will be in line with the world's advanced level.